NEW STANTON, Pa. — Volkswagen built over 1.1 million cars at the New Stanton factory over a ten year period, but the company’s gamble on North American production was problematic from the start and the last car rolled off the line on July 14, 1988.

Construction of the factory began in 1969 on a 1,200 acre site adjacent to the Pennsylvania Turnpike. The Chrysler Corporation succeeded in building a 2.1 million-square-foot shell of a factory, large enough to cover 37 football fields, before dropping sales and company financials put the plant on hold.

Chrysler would revisit the project in fits and starts over the next decade until the abandoned shell caught Volkswagen’s eye. Volkswagen was keen to move production to the U.S. to reinvigorate sales hurt by the strong West German deutsche mark and intensifying competition from Japan.

Volkswagen needed a sales success and a popular replacement for the Beetle to guarantee the company’s future. The acquisition of Audi in 1964 set the stage for the transition to the front-wheel-drive Golf, which was rebadged as the Rabbit for the U.S. market, using Audi’s expertise in water-cooled engines.

The economical hatchback Golf/Rabbit debuted in 1974 and arrived on the world market at the perfect time. This was particularly the case with the diesel version, as Americans felt the energy crunch of the late 1970s.

The design was so iconic and efficient that it would remain in production for 25 years, and sold over a million units within the first three years of production.

With the Golf successfully launched in Europe, an estimated $70 million worth of incentives and loans helped lure the German automaker to Pennsylvania in 1976. Volkswagen spent about $250 million to get the dirt-floored former-Chrysler factory completed and operational. Volkswagen, which had been selling German-imported Rabbits at a loss since 1975, hoped the Pennsylvania factory would lower production costs.

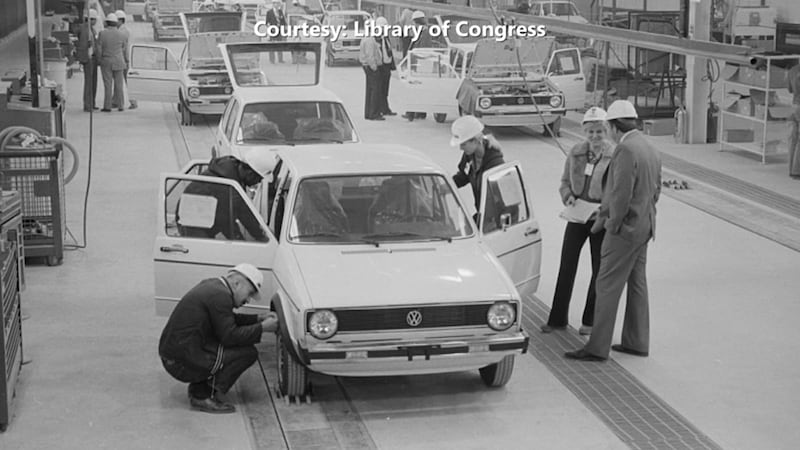

The first car, a white Rabbit, rolled off the line on April 10, 1978, and was promptly shipped off to the Volkswagen factory museum in Wolfsburg.

With the first car officially on the books, Volkswagen became the first foreign automaker to build cars in the U.S. since 1931.

Its predecessor, Rolls-Royce, opened a factory in Springfield, Massachusetts in 1919 and employed 1,200 workers up until the Great Depression forced the company to retreat.

Though similar in appearance to the German-built Golf, the U.S.-built Rabbit was altered for American tastes with softer suspension, different interior colors, factory-installed air conditioning, larger bumpers and parts that were progressively sourced more from American suppliers as production ramped up.

American-made Rabbits were most easily spotted by their rectangular headlights, which contrasted with the round headlights found on models made in the world. But while the Rabbit’s initial debut was well-timed to the market, the U.S.-built Rabbits were fundamentally a four-year-old design.

Initially, the plant was an unquestionable success, with production targets met on time and on budget, though strikes caused some early hiccups.

Volkswagen had tried to keep the plant from unionizing, but failed to pay the promised wage rates, so workers rallied around the chant of “No money? No bunny!” They joined the United Auto Workers union (UAW) and signed a contract to organize the plant in 1979.

The factory was soon assembling Rabbits from 5,400 individual parts, cranking out 800 cars a day, 50 an hour. That rate would increase to over 1,000 cars a day within a couple months.

Shortly after the plant opened, Volkswagen released a small pickup based on the Rabbit. Built exclusively at the Westmoreland factory, it targeted other made-for-America foreign pickups like the Subaru Brat.

The Rabbit Pickup would become known as the Caddy, starting with the 1982 model year, with production shifting to Yugoslavia in 1983. That country’s 1991 civil war ended European production of the Caddy, but Volkswagen’s South Africa factory continued to build it until 2007, though it is unclear whether the tooling was moved there from Yugoslavia.

Unfortunately, as fuel prices stabilized and competition increased, the Rabbit’s charm continued to wear off. A reluctance by Volkswagen to update the car left it hamstrung in a marketplace full of suddenly competitive Japanese brands with significantly fresher product lines.

By 1981, dropping sales prompted production cuts, which led to shutdowns and layoffs.

As a recession loomed in the early 1980s, Volkswagen’s plan was fracturing at the Westmoreland factory. Quality continued to lag the lower-priced Japanese competition, while labor disputes and grievances were becoming common and racial discrimination and incidents were reported too. A discrimination lawsuit brought against Volkswagen by the UAW was settled in 1989 for over $700,000.

The factory’s capacity was estimated to be 240,000 vehicles annually, but the closest Volkswagen came was 200,000 in 1980. Of the 20,000 jobs Pennsylvania officials expected, the peak at 5,700 was brief and by 1984 had settled down to just 1,500 working at the plant.

Volkswagen tried to revive interest in the cars with the introduction of a high-performance variant, the Rabbit GTI, and with a completely new Golf design in 1984, but sales continued to fall. Attempts to attracts American buyers with a sedan version, the Jetta, also fell flat.

The assembly line was stopped during the week of Thanksgiving 1987 so that Volkswagen officials could announce its intention to close the plant in the next six months. Workers have since said that they were not surprised by the decision, but going home to a feast that year was tainted nonetheless.

The final car, a white, two-door 1989 Golf, rolled off the assembly line with little fanfare on July 14, 1988. It was the 1,197,411th car to be built at the plant.

Workers’ hopes quickly evaporated that another automaker, thought to be Ford, would quickly move in to take over the plant.

Volkswagen’s annual losses at the plant were estimated to be around $120 million.

TRENDING NOW:

In retrospect, Volkswagen officials admitted that adapting the Chrysler facility imposed limitations and resulted in an inefficient workflow, with body panels coming from West Virginia and many parts remaining sourced from Germany, which made the Rabbit about $2,000 more expensive than its closest rival, the Honda Civic.

The factory tooling and production equipment for the Jetta was sold to First Automobile Works (FAW) of Changchun, China. A team of Chinese workers was trained on the equipment in Pennsylvania before it was shipped to China. FAW would continue to build Jetta variants until around 2012. Speculation has been that Volkswagen retained the Golf tooling for its South Africa factory.

Volkswagen’s production efforts in Pennsylvania led the way for other foreign automakers to open factories in the U.S., though the company would continue to struggle in the American market.

The company was dealt another major blow in December 1988, when Volkswagen of America’s CEO and marketing director, James Fuller and Lou Marengo, were killed by a terrorist’s bomb on Pan Am Flight 103 over Lockerbie, Scotland, while returning from a meeting in Germany.

Volkswagen’s sales in the U.S. bottomed out in 1993, and in 2008, Volkswagen announced it was returning production to the U.S. with an all-new factory in Chattanooga, Tennessee. The new facility started production in 2011 and it, combined with a host of other foreign brands, outproduced domestic carmakers in U.S. production tallies for the first time in 2018.

In 1990, Sony leased the plant and started manufacturing cathode-ray tubes (CRTs) for its televisions and displays. Sony invested around $300 million get the factory restarted. At its peak, Sony employed more than 3,000 workers, but advances in consumer electronics made CRT televisions obsolete and by 2010 the factory was closed again as flat-panel televisions conquered the market.

The Pennsylvania Industrial Development Authority took over the plant and then turned the property over to RIDC, which manages it today. RIDC has successfully leased out portions of the plant to different companies, totaling about 1,000 employees, along with the Advanced Technology Center of the Westmoreland County Community College.

Cox Media Group